Interdisciplinary interaction is at the heart of our integrated drug development model. Our API, Drug Product, Solid State Chemistry, Material Sciences, Analytical Development, Quality Control, Regulatory and Quality Assurance experts are all at the table when critical development decisions are taken. Along with our clients, we know this is the right approach for tomorrow’s challenges. The same integrated thinking and coordination continues at the commercial manufacturing stage.

Our high-end capabilities combined with, our certified facilities and 550 scientists deliver excellence for new chemical entities and cell therapy development from three sites: Abingdon (UK), Verona (Italy) and Modena (Italy).

Our solutions are customized to meet our clients’ requirements with drug development approaches guided by QbD expertise, at any stage of development and both at API and drug product levels.

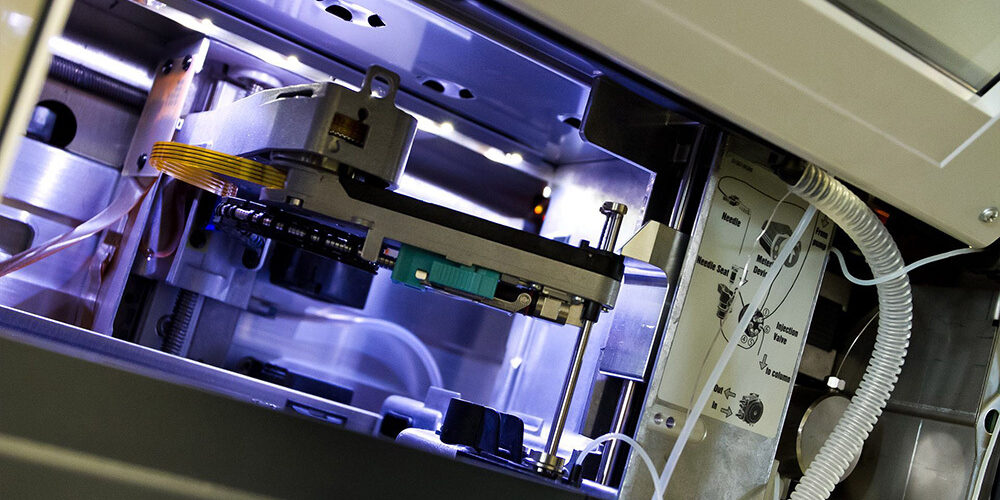

API Commercial Manufacturing Capabilities

Evotec’s commercial production capabilities consist of registered multi-purpose manufacturing facilities in Abingdon (UK).

Our facilities are designed and perfectly adapted to provide reliable and high quality commercial production of Active Pharmaceutical Ingredients. They are all ISO 14001 certified and licensed to handle Controlled Substances.

Learn More

- Key Considerations for API Process Development and Optimization >

- Commercial Active Pharmaceutical Ingredient Manufacturing Challenges >

- API Manufacturing: Excellence in Every Molecule >

- White Paper: How to go from API to PAI >

- White Paper: Evotec’s High Throughput Experimentation Platform in Drug Discovery and Development >

- Rescuing the Unsolvable – A Case Study >

- Webinar Series: Mastering Quality By Design >

About the Abingdon Site (UK)

Our site in Abingdon, Oxfordshire, is fully registered with MHRA as a “Manufacturer and Distributor of Active Substances to be used as Starting Materials in Medicinal Products for Human Use”.

In 2010, we performed and successfully completed an extensive FMEA study to establish true risks of cross contamination whilst in multi-purpose production mode.

We also worked extensively with MHRA who have provided certification for full multi-purpose manufacturing with high potent materials.

About the Verona Site (Italy)

At our site in Verona we have a kilolab / hydrogenation unit and a pilot plant, both approved by AIFA (the Italian Medicines Agency).

kilolab/hydrogenation unit cGMP production capabilities:

- Capacity up to 5 kg batches

- Six reactor modules:

- 50 L Hastelloy reactor

- From 5 to 20 litres mobile glass Jacketed Lab Reactors

- Temperature capabilities from -80 °C to +150 °C

- Pan filters, tray dryers, and Hastelloy filter-dryer

- Hydrogenation capabilities (up to 20 L scale):

- Temperature capabilities from -20 °C to +220 °C

- Pressure range: up to 40 Bars

Pilot plant cGMP production capabilities:

- Capacity – up to 50 kg batches

- 5 Vessel Streams

- Up to 100L glass-lined reactors

- Up to 400L Hastelloy reactors

- Hydrogenation capabilities (up to 20L scale)

- Temperature capabilities from -80 °C to +140 °C

- Pan filters, tray dryers and Hastelloy filter-dryers

- Purified water system

- Containment to 1 µg/m3

- Operates 16/5

About the Cell Therapy Factory in Modena (Italy)

Our cell factory in Modena can perform all production steps of ATMP manufacturing, from development to production, cold temperature storage and quality control. Various steps take place in dedicated zones within the facility, in compliance with the highest GMP requirements based on regulatory agency approval.

The GMP manufacturing facility is designed with clean classified areas from grade A to D, surrounded by unclassified technical areas. It is composed of:

- The cell factory: Equipped with 5 sterile cleanroom/manufacturing suites, suitable for aseptic manipulation of sterile medicinal products (Grade A/B cleanroom) according to EU and US cGMP rules

- A class cGMP warehouse with ambient and +4°/-20°C storage, with a dedicated airlocks and a Grade D transfer material zone

- Cryogenic space: For qualified controlled storage at -80°C to -196°C with vapor phase liquid nitrogen under 24-h monitoring system and back-up power

- QC laboratory: Equipped to perform microbiologic tests to monitor classified rooms and to execute quality and safety controls on intermediate and final products

- R&D laboratory: For pre-GMP manufacturing development and product optimization

- Control room: Enabling monitoring of all the critical parameters via SCADA

Rooms 1 and 2: Cell factory and GMP warehouse are cleanroom spaces of 450m2

Drug Product Commercial Manufacturing Capabilities

Our drug product commercial production facility in Verona (Italy), is approved by the Italian authorities (AIFA). Our facility stands ready to embark on the manufacture of commercial batches of a diverse range of pharmaceutical dosage forms, including granules, plain tablets, coated tablets, and hard capsules. Validation campaigns comprising three demonstration batches for various dosage forms were successfully completed and data provided to AIFA to support the authorization requests.

The facility is fitted with equipment trains suitable for production of granules by wet granulation, employing either high shear or fluid bed technologies. Granules (as intermediates or bulk finished products) seamlessly integrate into downstream processes such as tableting or hard capsule filling. The facility also offers a perforated pan coater, enabling precise tablet coating.

Our Verona facility is a perfect fit for smaller batch sizes often associated with niche/orphan drug products. This facility is ideally positioned for registration campaigns for large commercial volume products. Top-level quality combined with flexibility deriving from a long-established experience with development projects allows an optimal balance between project speed and collection of data for successful approvals of registration packages.

While no commercial products are currently produced, our facility presents an interesting opportunity for a seamless transition of your development project, applying the knowledge built during the pharmaceutical development to the realization of robust commercial products.

One of our distinctive strengths lies in the potential to seamlessly integrate drug product and API manufacturing, both thriving "under the same roof" in our Verona site. This convergence streamlines processes, minimizing the risk of technical problems and unwelcome delays.

As you contemplate your pharmaceutical journey, consider our Verona facility as the ideal partner for your pharmaceutical solutions. Our commitment to precision, innovation, and seamless collaboration awaits, offering you the means to bring your product to the patients.