Evotec excels in challenging Orally Inhaled and Nasal Drug Product (OINDP) development, leveraging nanotechnology and therapeutic advantages. Multidisciplinary teams drive inhaled product development for Phase I to late-stage clinical studies, offering tailored plans and robust strategies. Inhalation Analytics and Material Sciences ensure quality, supported by specific expertise and an integrated approach.

Orally Inhaled & Nasal Drug Products

It is widely recognized that the development of orally inhaled and nasal products (OINDPs) is extremely challenging, thus requiring a rigorous approach to formulation development, analytical testing and CMC support. However, OINDPs offer significant opportunities for drug development primarily driven by therapeutic advantages over other dosage forms, and new formulation technologies based on nanotechnology.

At Evotec, inhaled drug product development is a major part of the integrated CMC portfolio with dedicated cross-functional teams working together on projects. The team develops inhaled products for new chemical entities (NCEs) and generics for clinical programs from Phase I to late-stage clinical studies, throughout our cGMP facilities in Italy and the UK.

Evotec proposes integrated and stand-alone development plans tailored to each project to increase success and save time. Our programs are supported by a dedicated Inhalation Analytics and Material Sciences team using state-of-the-art equipment to characterize and define the drug product's quality attributes.

The integrated approach we apply, alongside our scientific expertise, provides robust and reliable development strategies for challenging pharmaceutical inhaled drug product programs.

We provide product development support for the following product classes:

- Dry powder inhalers (DPI)

- Nebulizers (solutions and suspensions)

Our Inhaled Product Development Capabilities

- Formulation development of dry powders and liquids designed to meet a quality target product profile (QTPP) with consideration of your final commercial process and support of the technology transfer

- Inhaled analytics and quality control (QC) within dedicated laboratories for Dry Powder Inhalers (DPI), and nebulizers for all stages of development up to and including commercial release and ICH-stability

- Active pharmaceutical ingredient (API): Chemical development and manufacturing service enabling industry-leading API route design and process development up to and including commercial supply

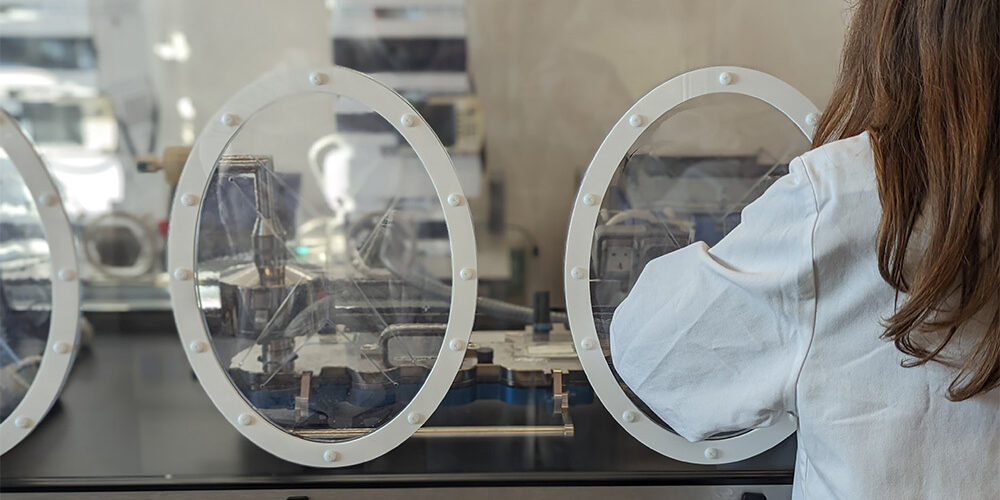

- cGMP clinical manufacturing: Dedicated inhaled production pilot plant clean room status ISO7, Grade 7 . Environmental controls and material handling up to OEB5 (<1µg/m3)

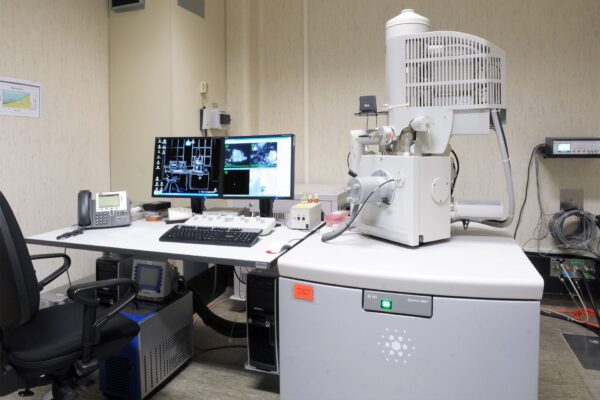

- Material science: Best-in-class laboratories for physical properties analysis, API solid form selection and crystallization development

- Quality assurance: FDA, MHRA and AIFA approved facilities

Formulation Development

- Developing, optimizing and scaling up dry powder inhaled, liquid and suspension formulations from first-in-human studies up to Phase III. The QTPP is considered from the very start in order to reduce the frictions in inhaled products development thus enabling robust GMP manufacturing

- Pharmaceutical particle engineering via spray-drying and nano-milling technology

- Developing NCEs and generic products (505j submission) based on platform technologies including high shear and low shear powder blending along with capsule filling equipment (volumetric and gravimetric)

Inhaled Analytics & Quality Control

- Laboratories exclusively dedicated to Dry Powder Inhalers (DPI) and nebulizers.

- Aerodynamic performance testing (NGI and DUSA) of inhaled products including

- Reverse engineering of multiple reference DPI products

- In vitro equivalence studies

- Inhaler device selection

- Optional NGI (next generation impactor) cooler, and breathing simulators

- APSD Data analysis performed by Inhalytix® validated software.

- Four advanced Climatically Controlled Environment systems(ClimateZone) ensure standardized temperature and humidity throughout crucial steps, complemented by antistatic devices neutralizing electrostatic charges.

- Method development and validation based on Quality by Design (QbD) principles in a fully validated GxP environment (from Phase I to Phase III).

- Fully validated, robust GMP Laboratory Information Management System (LIMS) ensures comprehensive data recording, supported by an electronically controlled (QRcode) sample management system for precise management of standards, samples, and columns. QC laboratories equipped with HPLC, UPLC, LCMS, GCMS, automated and manual dissolution, ICP and KF instruments

- Full ICH (International Council for Harmonisation) stability storage testing and ASAP (Accelerated Stability Assessment Programme) studies by using the validated ASAP Prime® software

API

- Risk-based approach for establishment of critical process parameters and robust processes to develop, optimise and manufacture small molecule APIs from preclinical to commercial; process validation is based on QbD, DoE (Design of Experiment) and PAT (Process Analytical Technology) methodologies

- API manufacture spans wide range of substances (including potent and controlled substances) at various scales (volumes ranging from 20 L to 1.600 L) within FDA, MHRA, AIFA approved GMP labs and pilot plants

- Activities include polymorph, salt and co-crystal screens, and design of crystal engineering strategies and crystallization processes

Material Sciences

- State-of the-art technologies to support integrated inhaled projects including

- Micromeritics (particle size, surface area, DVS, pycnometry, powder rheology, wettability)

- Spectroscopy (FTIR, Raman, NMR)

- X-Ray Diffraction (XRPD, including non-ambient and 2D)

- SAXS

- Thermal analysis (DSC, TGA, TGA-IR)

- Microscopy (PLM, ESEM+EDX)

- Integrated studies include

- Assessment of micronization and storage conditions on amorphous formation and particle agglomeration

- Specific surface area relationship to particle size and surface morphology

- Rheology for cohesive powders

cGMP Clinical Manufacturing

- Pilot plant with dedicated area for the manufacture of inhaled products with ISO 7 classified facilities (equivalent to Grade C) with suitability for highly potent compounds up to OEB5 (<1μg/m3)

- Controlled environmental conditions within manufacturing area (often required for inhaled products)

- Batches up to a scale of 100k units for DPI capsules with 100% check weight control

- Packaging includes bottling, blister packing and labelling

Quality Assurance

- GMP activities overseen by independent Quality Assurance unit ensuring compliance and providing customer and regulatory audit support

- Long-standing relationships with preferred partners to bring specialist advice on regulatory aspects

- FDA, MHRA and AIFA approved facilities

Read More

- Precision in Every Breath: Holistic Inhalation Drug Product Design and Development Factsheet >

- Tackle APSD Data Variability with Confidence! Factsheet >