At Evotec, as pioneers in integrated drug discovery and development, we specialize in handling a broad and continuously evolving portfolio of New Chemical Entities (NCEs). Our services span the entire development spectrum- from microgram-scale samples for compound management to kilogram- and 100 kg-scale active pharmaceutical ingredient (API) production.

Our biologics capabilities are equally comprehensive, supporting projects from early-stage lab research through to full manufacturing scale-up with dedicated, state-of-the-art facilities in France and on the U.S. West Coast.

Our operations span the full value chain - and with that comes a responsibility: to protect our people and partners while advancing therapeutic innovation.

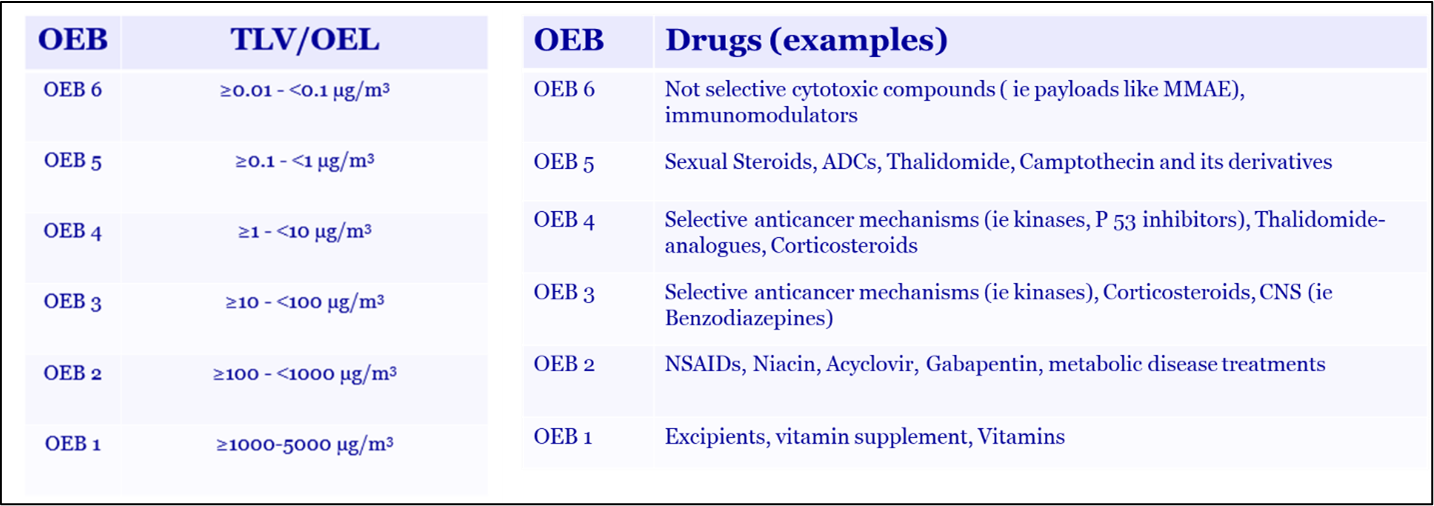

One of our key differentiators is our tailored and science-based approach to occupational health and safety (OHS), especially in the handling of potent and highly potent compounds. In a pharmaceutical landscape marked by increasing potency and complexity, we have developed and implemented a granular, risk-based Potent Compound Strategy built around a robust Occupational Exposure Banding (OEB) system - extending through to OEB6 with clearly defined thresholds.

Leveraging its integrated expertise in occupational toxicology and industrial hygiene, EVOTEC delivers tailored solutions to ensure the safe handling of New Chemical Entities (NCEs) in the workplace, including those classified up to Occupational Exposure Bands (OEB) 5 and 6

What Is Our Potent Compound Banding System?

Our internal OEB framework classifies compounds based on their Threshold Limit Values (TLV) or Occupational Exposure Limits (OEL), ensuring that the appropriate containment measures are in place.

We go a step further by setting a precise cut-off for OEB6, allowing us to implement containment strategies for the most potent compounds, such as antibody-drug conjugate (ADC) payloads and other ultra-potent modalities.

Moreover, in cases where an NCE is insufficiently characterized, Evotec default classifies it under OEB4, ensuring a conservative and protective approach until more data becomes available.

Why We Distinguish Between OEB5 and OEB6: A Scientifically Grounded Approach

In occupational health, precision is not just a principle - it’s a necessity. This is especially true when dealing with highly potent compounds, where even minute differences in exposure levels can have significant implications. That’s why we make a clear distinction between OEB5 and OEB6.

While both bands represent extremely low occupational exposure limits, the step from 0.1 µg/m³ (OEB5) to 0.01 µg/m³ (OEB6) marks a critical threshold. Scientifically, this shift reflects a deeper understanding of toxicological risk at ultra-low doses. Operationally, it introduces a new level of complexity.

The real challenge begins below the OEB6 threshold. At these levels, achieving effective containment and reliable industrial hygiene monitoring becomes exponentially more difficult. Factors such as the physical state of the material, the scale of handling, and the sensitivity of analytical methods all play a crucial role. These are not just technical hurdles - they are defining factors in ensuring worker safety.

By formally recognizing OEB6, we enable more precise risk management and foster innovation in control technologies. Our commitment to this distinction is part of a broader effort to stay ahead of the curve, continuously improve our practices, and support the industry's push toward safer, more sustainable handling of ultra-potent compounds.

A Smart, Scalable Strategy for a Complex Pipeline

With Evotec’s highly integrated model - covering everything from hit identification to commercial manufacturing - our potent compound strategy is designed to scale with the project, never applying a one-size-fits-all approach.

This is enabled by:

- A dynamic Exposure Control Matrix (ECM) serves as a structured framework for determining appropriate containment strategies. It integrates factors such as the Occupational Exposure Band (OEB), batch scale, and the material’s physical characteristics (e.g., dustiness, volatility) to guide the selection of both engineering and administrative controls.

- A rigorous onboarding process for every new compound or project.

- Cross-functional risk assessments involving EHS, industrial hygiene, toxicology, quality and operations.

- A comprehensive industrial hygiene plan and program is established to safeguard personnel health while also supporting strategic business decisions on containment investments and ongoing improvements.

How Do We Execute This Strategy?

1. Containment & Engineering Controls

Containment solutions - ranging from ventilated balance enclosures to isolators and dedicated suites - are tailored to the specific risk level and stage of the process. Each setup is validated using surrogate testing prior to initial use. A robust chemical industrial hygiene program is in place to ensure worker protection.

2. Training & Skill Development

- Training and on-the-job training with fluorescent surrogates ensures correct technique and full understanding of containment principles.

- Established instructions, procedures, and guidelines are in place to ensure consistency and clarity in daily operations

- EHS-led training in each Evotec site ensures regional consistency with local regulations and international best practices.

- People center approach: Skilled operators and researchers with deep expertise in the field and strong academic backgrounds are integral to ensuring high standards in containment practices and innovation

3. Toxicology & Exposure Science

- An in-house industrial toxicologist supports compound onboarding and project reviews to ensure accurate hazard characterization.

- Trained industrial hygienists in each region conduct routine monitoring, air sampling, and validation of exposure controls.

4. Integrated Oversight

- A dedicated Hazardous Substance Team governs substance classification, material flow, and change control processes.

- Continuous improvement through internal audits, CAPAs, and incident learning.

Partner Confidence Through Occupational Excellence

At Evotec, safety isn’t a barrier to innovation - it’s a foundation. By implementing advanced containment strategies supported by deep toxicological and industrial hygiene expertise, we ensure the safe, compliant, and scalable handling of even the most potent NCEs.

This commitment gives our partners the assurance that their compounds - no matter how complex or potent - are managed with the utmost care, integrity, and professionalism.

Ready to Scale Your Discovery Safely?

Connect with us to learn more about how Evotec’s potent compound handling capabilities can support your program from discovery through to commercial success.